Automotive

Advanced solutions for automotive assembly and welding

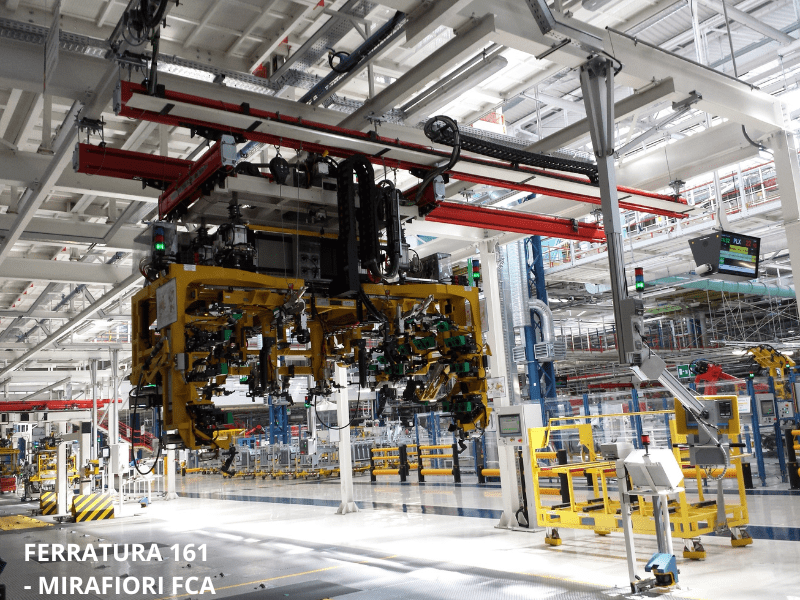

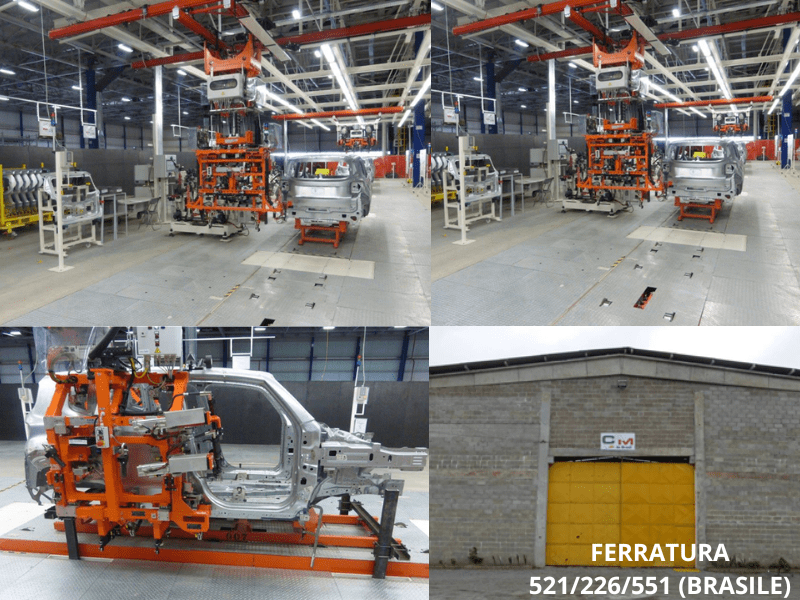

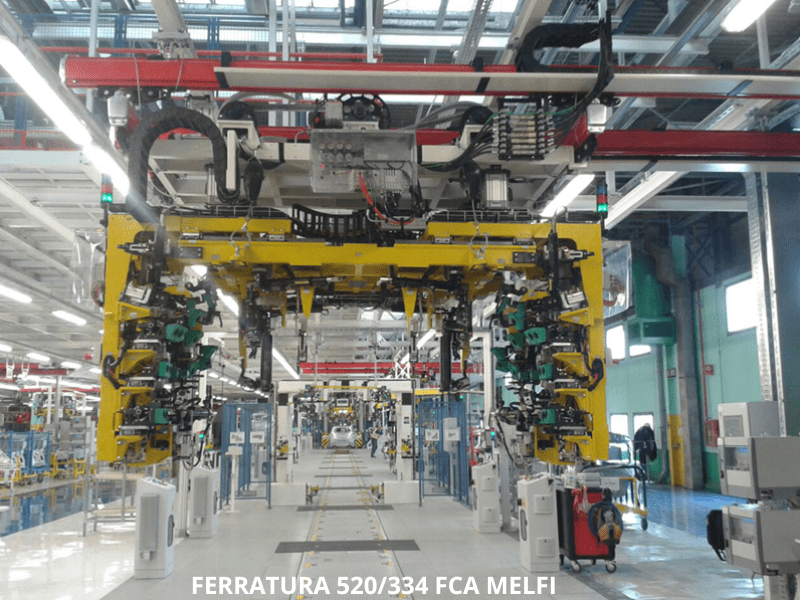

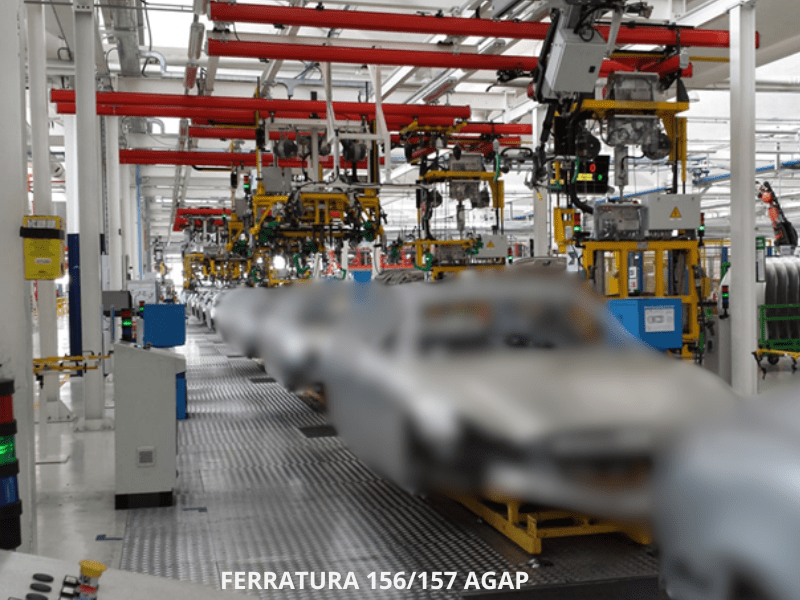

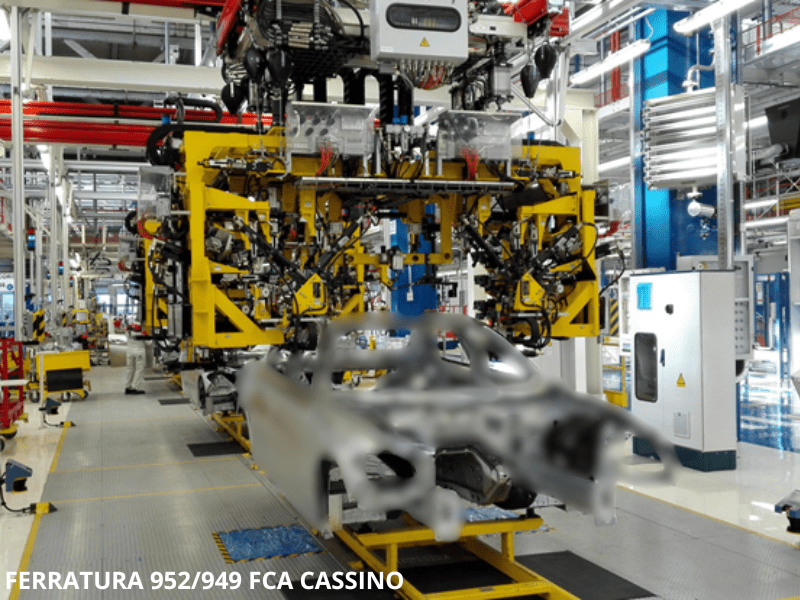

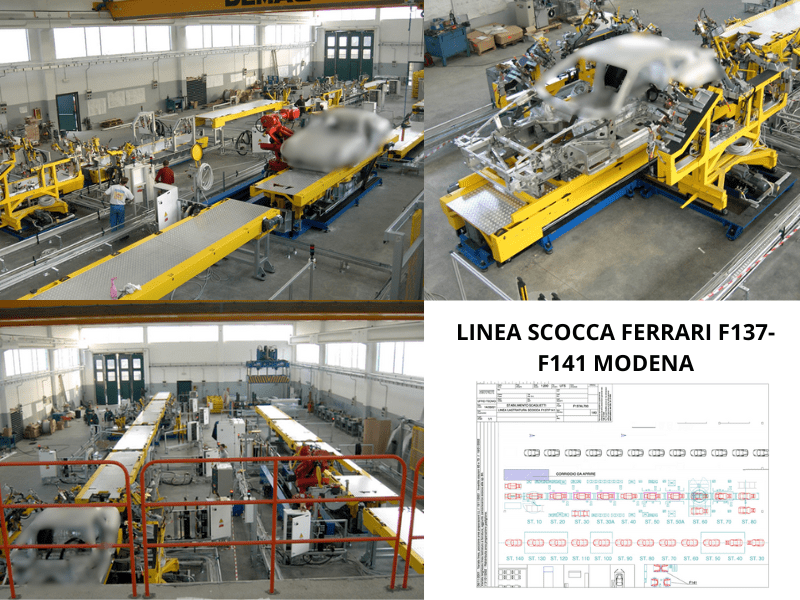

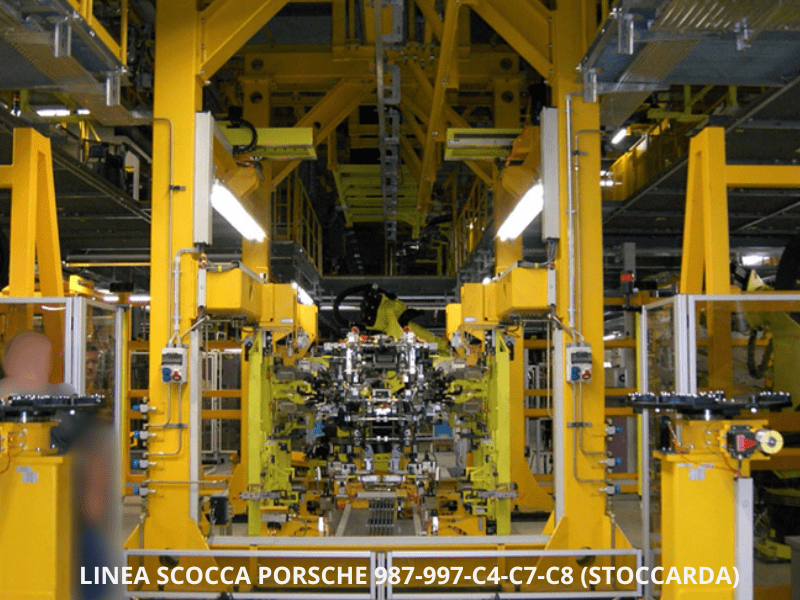

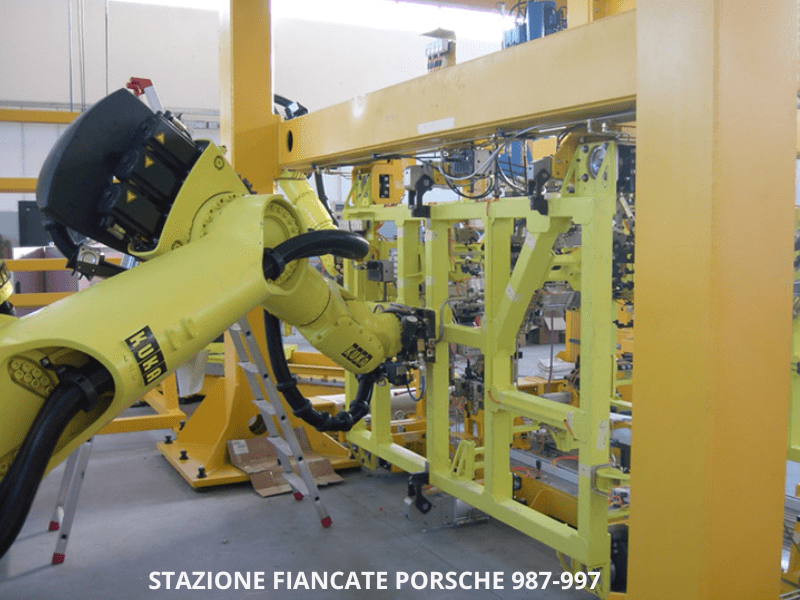

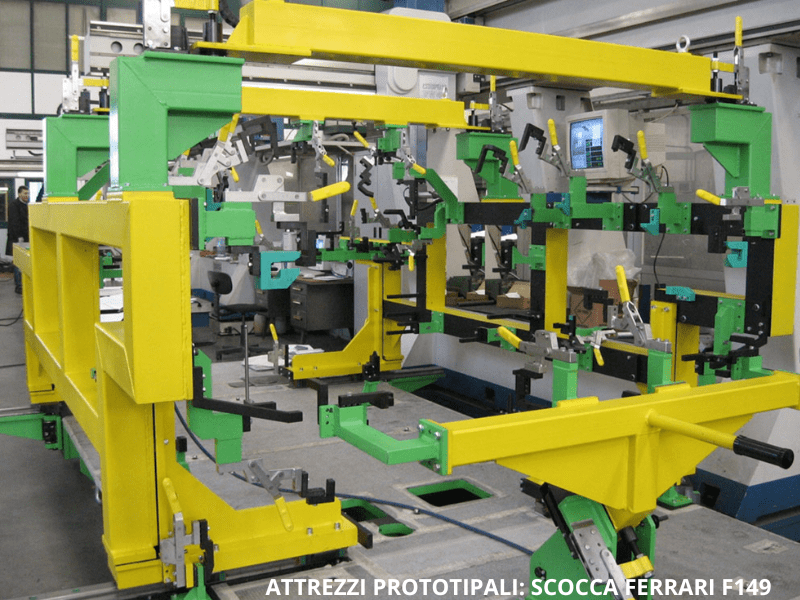

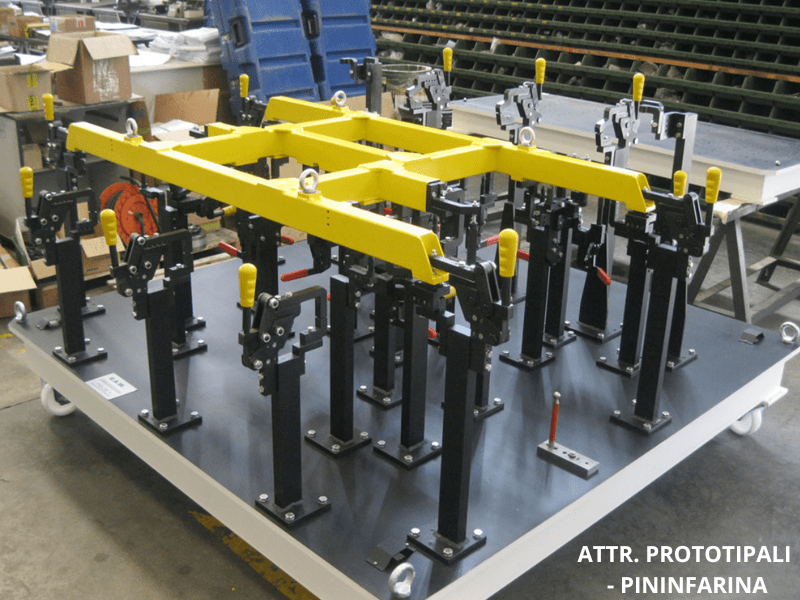

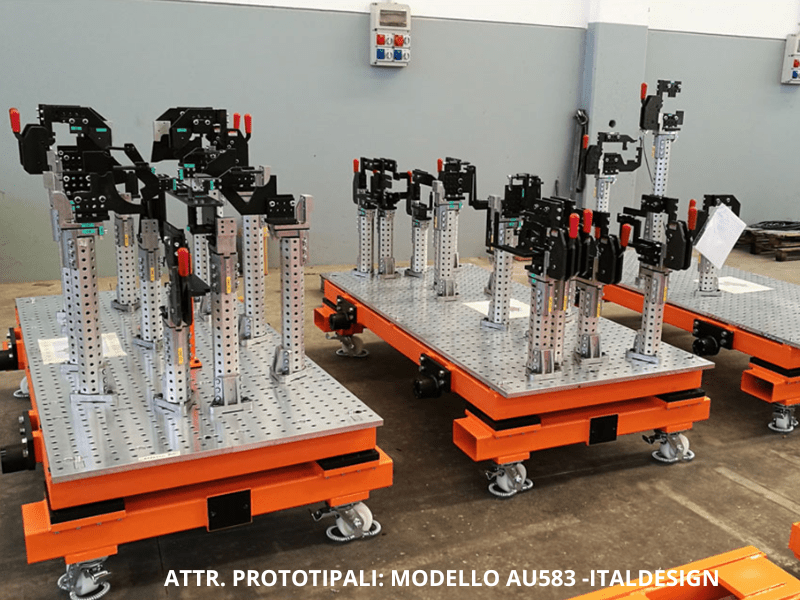

We specialise in the design and construction of solutions for the assembly and welding of bodywork components in the automotive business, adapting to client specifications (such as Integra 6/7 and Tisax), including:

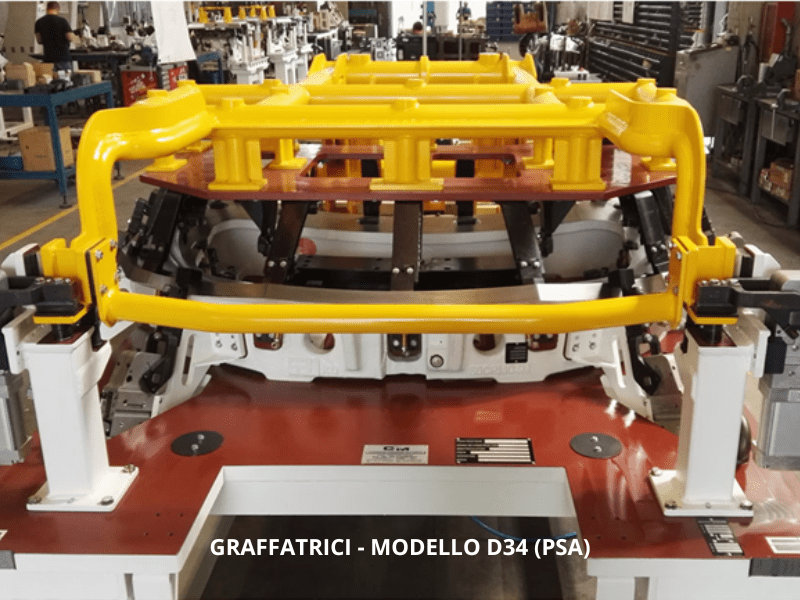

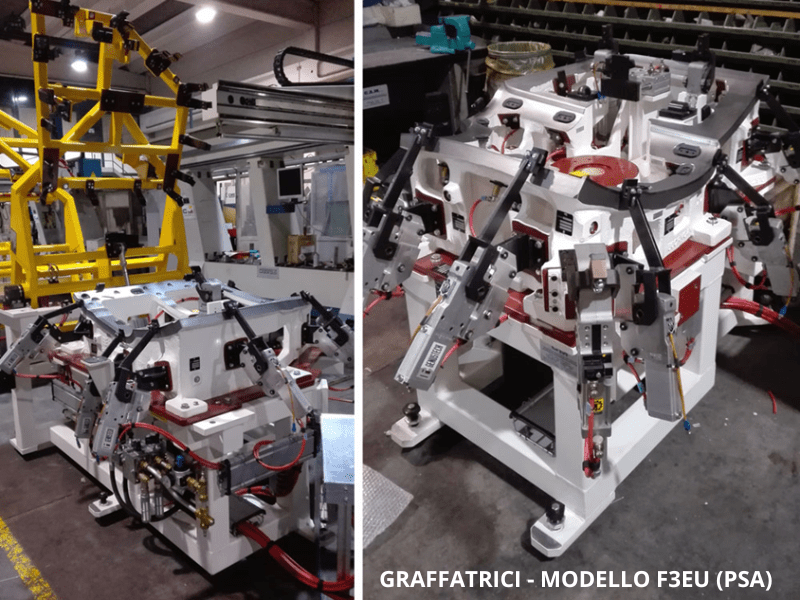

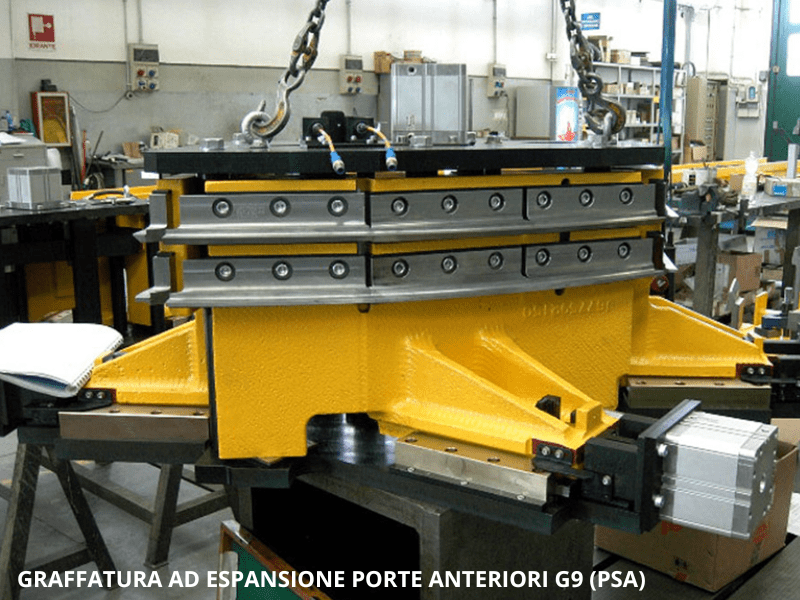

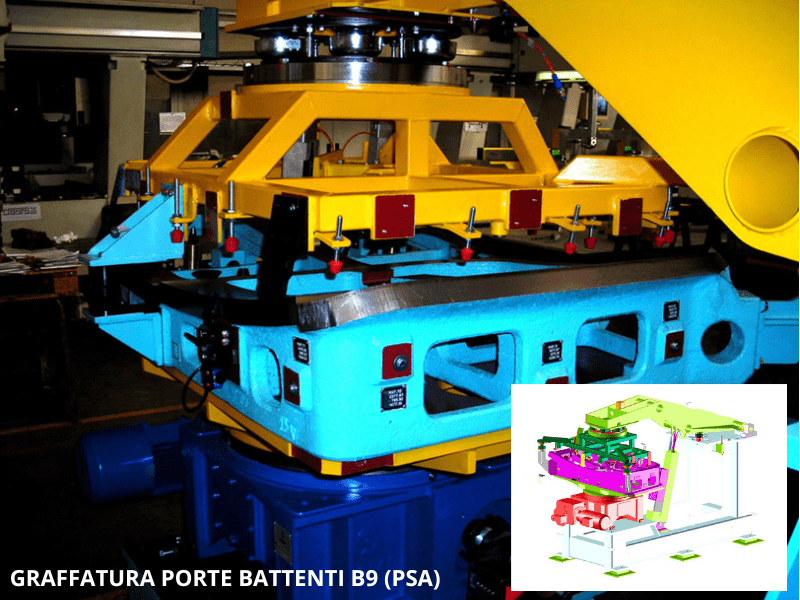

- Moving parts locking/assembly lines (manual and automatic)

- MIG/MAG welding machines

- Islands and automatic assembly lines for car body/chassis/sub-assemblies

- Islands and automatic assembly and hemming lines for moving parts

We develop advanced projects, simulations, virtual commissioning/off-line programming and complete designs through our integrated systems and an extensive software fleet compliant with the specifications of the main European car-makers.

A completely in-house production is guaranteed, with our automation department being able to provide complete solutions (electrical, pneumatic, software and robots) adapted to the needs of each client.

Specific teams for each department are dedicated to assembly and functionality tests to complete/certify the systems in the dedicated areas in CAM and by the end client (up to SOP).

Knowledge of the main types of hot/cold joining is the basis of technical development of:

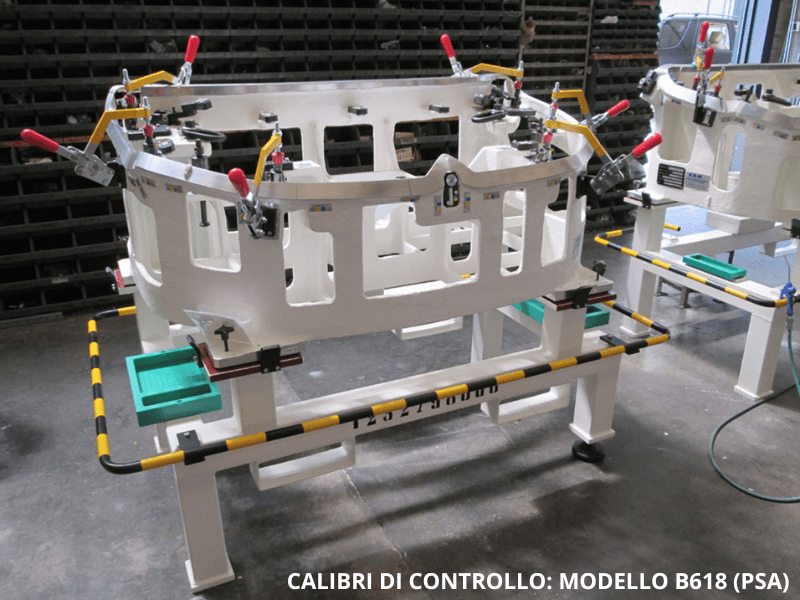

In addition to the main plants, we can provide small pre-series productions, effective technical plant assistance at the client’s premises along with equipment such as test benches, control gauges and process logistic systems.

Automotive Projects

And many others… work in progress