Aerospace

Advanced solutions for the aeronautical and aerospace sectors

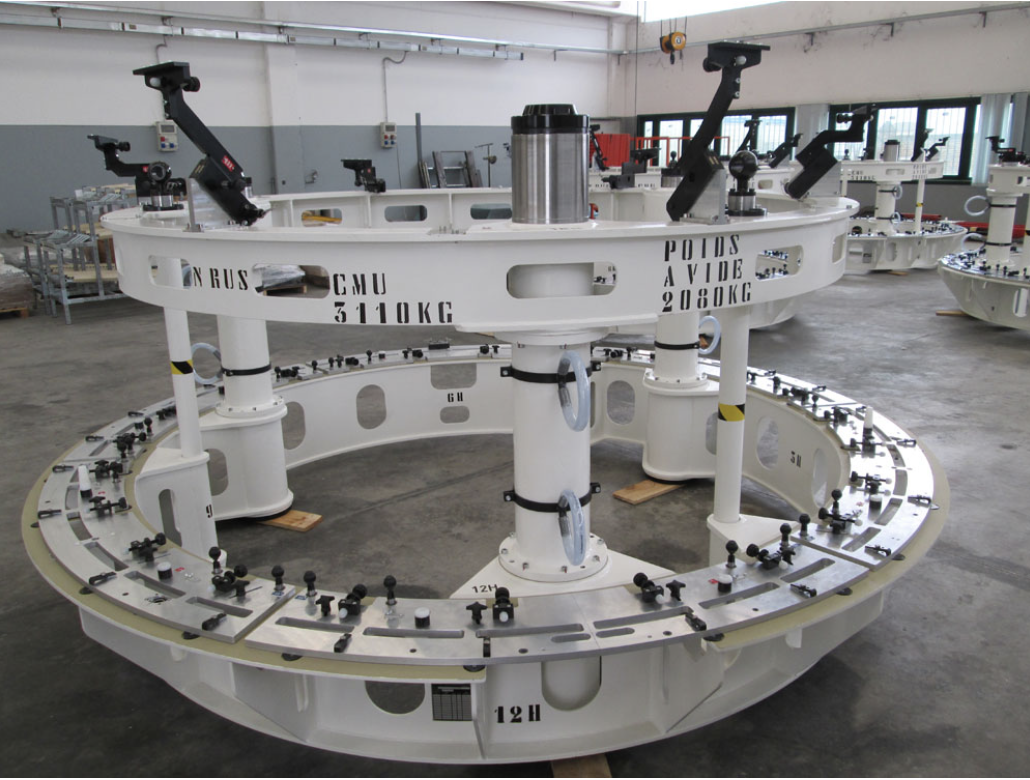

We design and manufacture integrated solutions for the aeronautical and aerospace sector, specifically:

- Assembly ladders

- Complete stations for assembly and measurement

- Maintenance equipment

- Component transporting equipment and systems

We guarantee extensive in-house experience in manufacturing processes such as multi-material welding (including aluminium in a dedicated booth).

As we work towards ISO 3834 – Welding Standard certification and have the WPS/WPQR with Internal Welding Coordinator/Inspector ISO 14731 and ISO 9712 Level 2 for VT-MT-PT-UT controls,

we also adopt cutting-edge tools in the control of welds with the RT and US “live” method, all with a view to providing the highest level of quality and flexibility.

We possess large 3-axis and 5-axis machining machines for production and painting in a dedicated booth.

Geometric checks are carried out using fixed and automatic control machinery, laser trackers and portable instruments such as the ZEISS T-SCAN (also in a temperature-controlled environment).

A specific team dedicated to the assembly and execution of static and dynamic tests is responsible for completing/certifying the installations in the dedicated areas in CAM and by the client.

We can likewise provide our internal staff with electrical, pneumatic and hydraulic systems with any relative designs and software implementations based on client standards.

In addition to the main systems, we provide suitable technical assistance and equipment such as control gauges and maintenance tools.

Aerospace Projects

and many others… work in progress